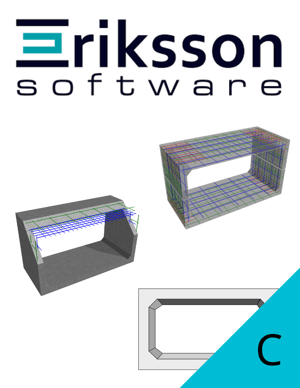

Precast or Cast-in-Place Concrete Culvert Design & Analysis

Eriksson Culvert is the most advanced engineering software for precast and cast-in-place box culverts, seamlessly combining the functionality of a state-of-the-art structural analysis engine with fully automatic design and analysis capabilities. Integration of the critical design tasks into one system means you get superior productivity and flexibility with improved quality control.

In auto design mode, Eriksson Culvert quickly analyzes and designs wall thicknesses and reinforcement sizes and spacing. A comprehensive reinforcement schedule containing rebar and mesh is produced, complete with all bar dimensions and bends. LRFD, Standard, AREMA, and CHBDC specifications are supported, as well as, both US customary and metric units.

The highly graphical user interface provides multiple views to render the design and present the results. Complete details of the design along with detailed calculations are provided. Powerful graphics show all rebar rendered in true 3D and a user-customizable truck library is included in the sophisticated live load capabilities.

With Eriksson Culvert, you can automatically design five different culvert types: four-sided, three-sided, multi-cell, type I, or type II. When a new job is started, the input boxes will each be initialized to reasonable default values in the following groups:

- Project Settings: Job description, governing specification, and operation mode

- Culvert Properties: Culvert dimensions and material properties

- Loads: Applied static loads, moving live loads, and seismic options

- Load & Resistance Factors: Override load & resistance factors as necessary

- Analysis Options: Specify run-time changes to basic assumptions and equations

- Reinforcement: Edit properties of rebar at any position

- Shear Steel: Enable and add shear steel for analysis

In Design Mode, Eriksson Culvert will determine the appropriate culvert properties such as reinforcement, slab thickness, and wall thickness. In Analysis mode, the user selects the slab and wall thicknesses, and sets most of the rebar sizes and spacing.

Calculations are automatically performed whenever an open dialog box is closed using the ‘OK’ button. Calculations are also recomputed when a previous job is restored. Because of its extremely fast calculation engine, Eriksson Culvert’s recalculation times are typically less than a few seconds. This results in the ability of the program to perform real-time calculations. That is, whenever a revision to the input data is made, calculations are automatically updated in the background, and the results are quickly made available to view in multiple formats.

The practical result of Eriksson Culvert’s method of performing calculations is that after editing the input, you can immediately view the effects on the design. In addition to the main view, results can be viewed via a text report, graphs, and a 3D rendering. The text report includes the input data, a complete listing of all shears and moments, the values at critical sections, the rebar schedule, a serviceability check, and the load combination results.

Eriksson Culvert is extremely user friendly, with one of its many benefits being an in-depth help system. When any dialog box is open, you can press the F1 key on your keyboard to get detailed information regarding the required input. Aside from the context-specific help, there are also help topics dealing with the general operation of the program and engineering theory as well. To access those areas, navigate to the ‘Contents’ tab located in the left pane of the help screen.

Key Features

- Auto-designs reinforced box culverts

- Supports multiple specifications (LRFD, Standard, AREMA, CHBDC)

- Ability to pre-set analysis options for specific governing agencies

- Multiple culvert types (box, 3 sided, type 1, type 2, multi-cell)

- Advanced moving load analysis

- AASHTOWare connectivity

- Seismic analysis